Quantitative Multielement Analysis of Solid Samples by ICPMS

Minimal Sample Prep

Accelerate workflows and measurement from weeks to hours

Solution-Level Accuracy

Achieve linearity and quantitation on par or better than liquid ICPMS

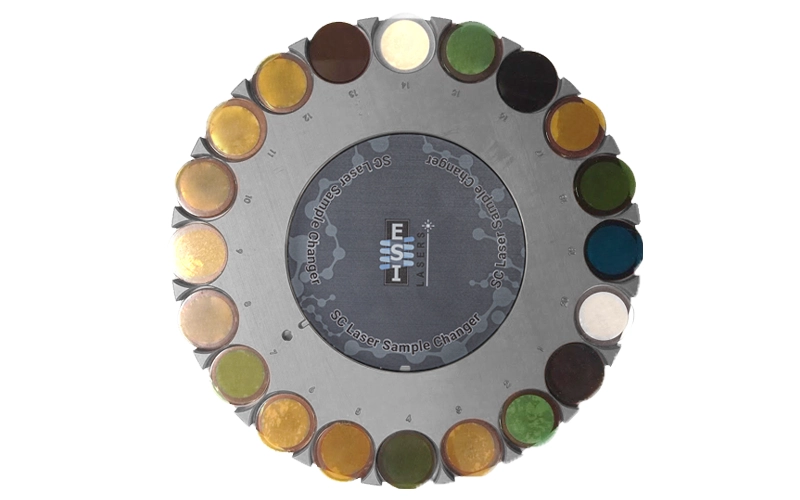

Robotic Sample Handling

Fully automated workflow, from sample handling to data reporting

Minimal Sample Prep

Accelerate workflows and measurement from weeks to hours

Solution-Level Accuracy

Achieve linearity and quantitation on par or better than liquid ICPMS

Robotic Sample Handling

Fully automated workflow, from sample handling to data reporting

SolidSample ICPMS Overview

A Faster, Safer Solution to Solid Sample Analysis

Improve Analytical Workflows, Data Quality, and Sample Turnaround

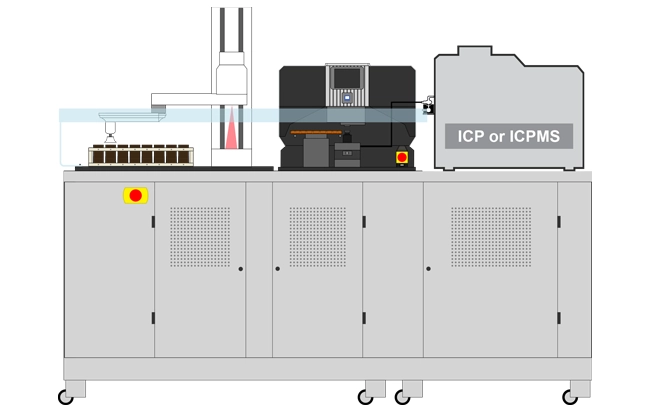

SolidSample ICPMS enhances elemental analysis for solid sample workflows by fully automating sample handling, direct solids analysis, and data processing. By eliminating labor-intensive and hazardous acid dissolution steps, SolidSample ICPMS improves throughput and lab safety. Using matrix-matched calibration standards that never expire, the system achieves analytical precision and accuracy once limited to traditional solution-based techniques. Whether processing dozens or thousands of samples daily, SolidSample ICPMS provides a scalable, reliable platform that streamlines operations, conserves resources, and achieves reproducible elemental data with minimal manual intervention.

- Automated 24/7 analysis of samples by ICP or ICPMS

- Integrated sample tracking enhances data reliability and integrity

- Acid-free sample preparation saves time, lowers costs, and improves lab safety

How it Works

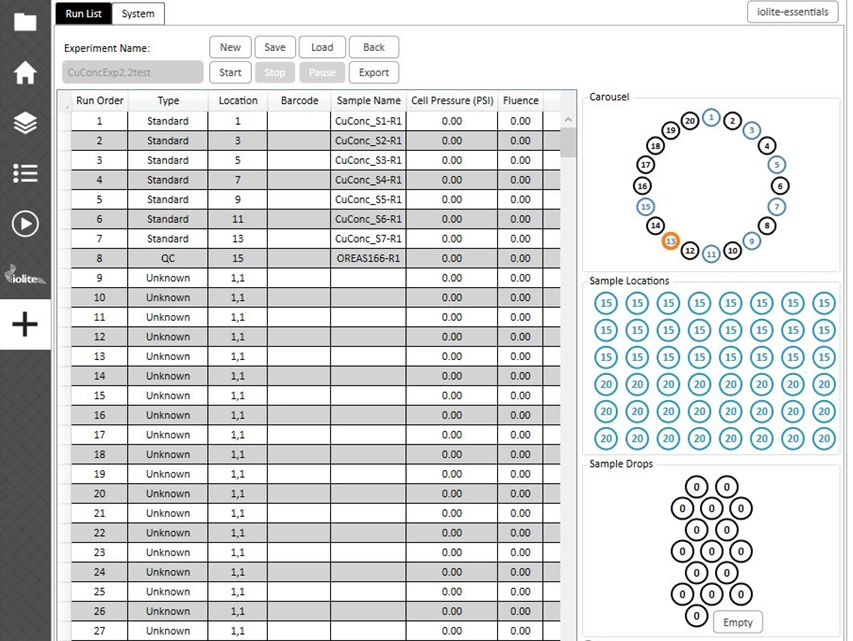

Complex workflows are simplified into a single, fully automated method with SolidSample ICPMS. Samples automatically transition through accomodation, barcode tracking, and analysis, before finally being re-accomodated. This automated method saves time and costs, reduces errors and increases throughput.

Applications

SolidSample ICPMS is designed for versatility, making it suitable for a wide range of applications.

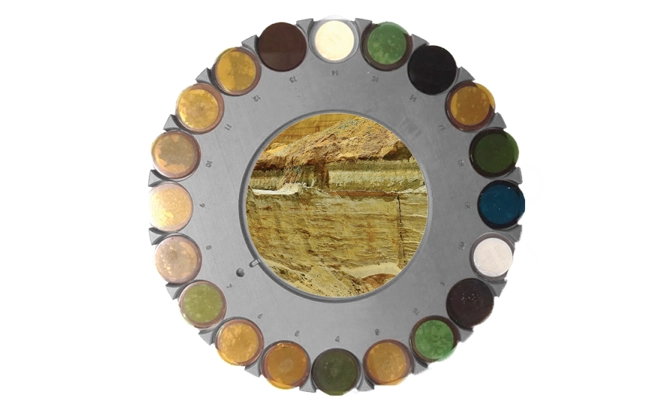

Sample Types

SolidSample ICPMS delivers accurate, reproducible elemental data across diverse sample types.

Primary Features & Benefits

Redefining Solid Sample Analysis

Transform solid sample analysis with automation. Get solution-level accuracy and real-time results—no acids, no labor, no downtime.

Eliminate Sample Digestion

- Acid-Free Sample Prep – Direct solid analysis eliminates hazardous reagents and minimizes contamination risk.

- Multielement Efficiency – Achieve higher analytical output compared with traditional four-acid-digestion workflows.

- Accelerate Workflows - Significantly reduce sample turnaround down to minutes.

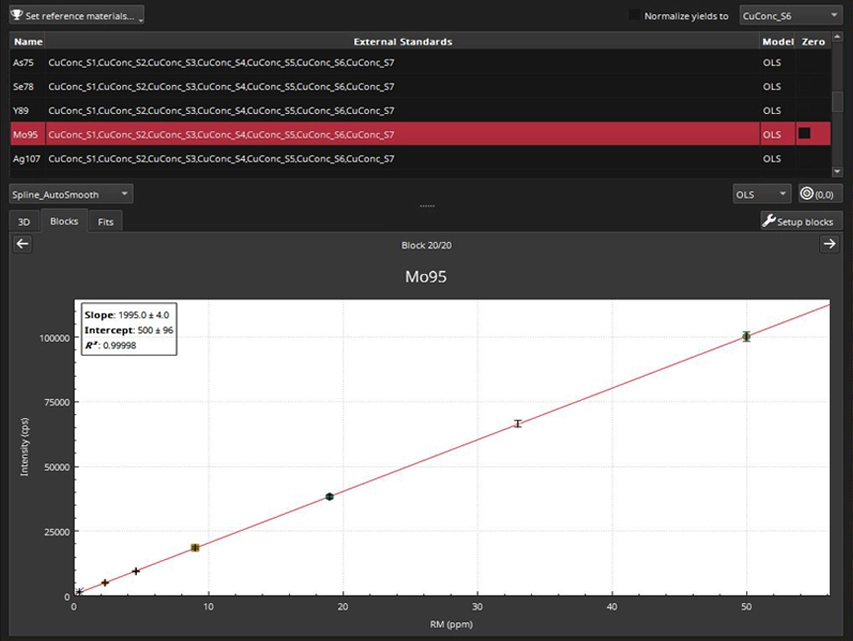

Solution-Level Accuracy

- SolidStandards Never Expire - Ensuring long-term analytical confidence.

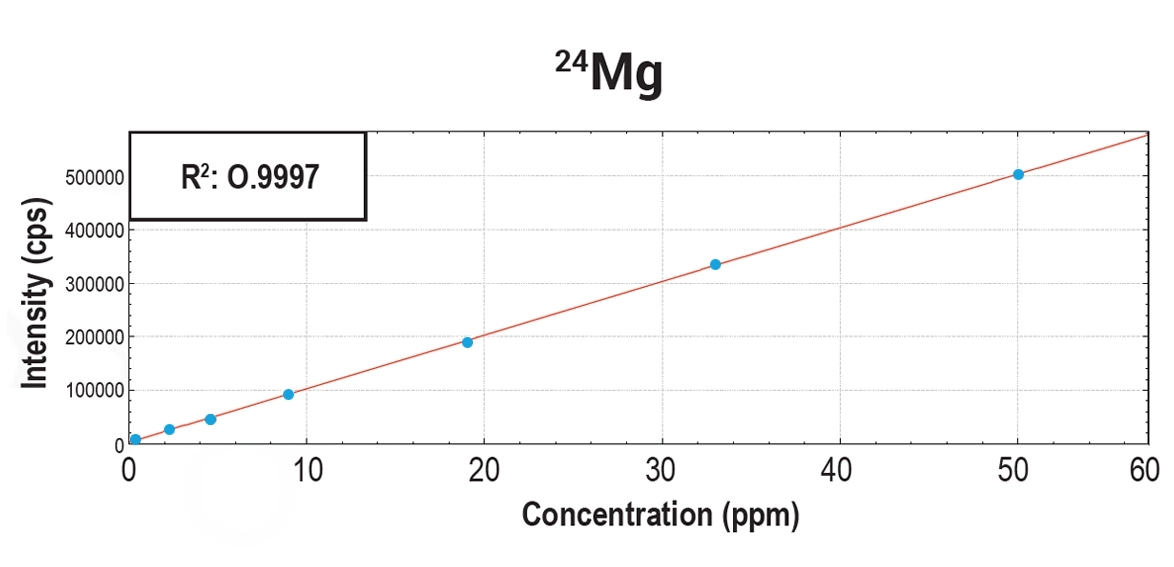

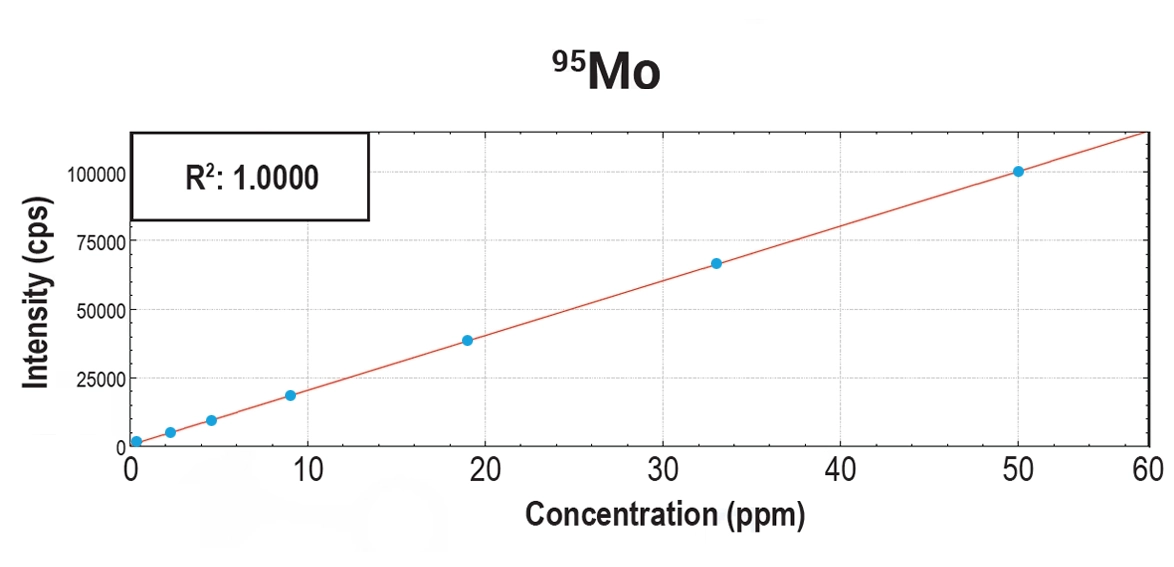

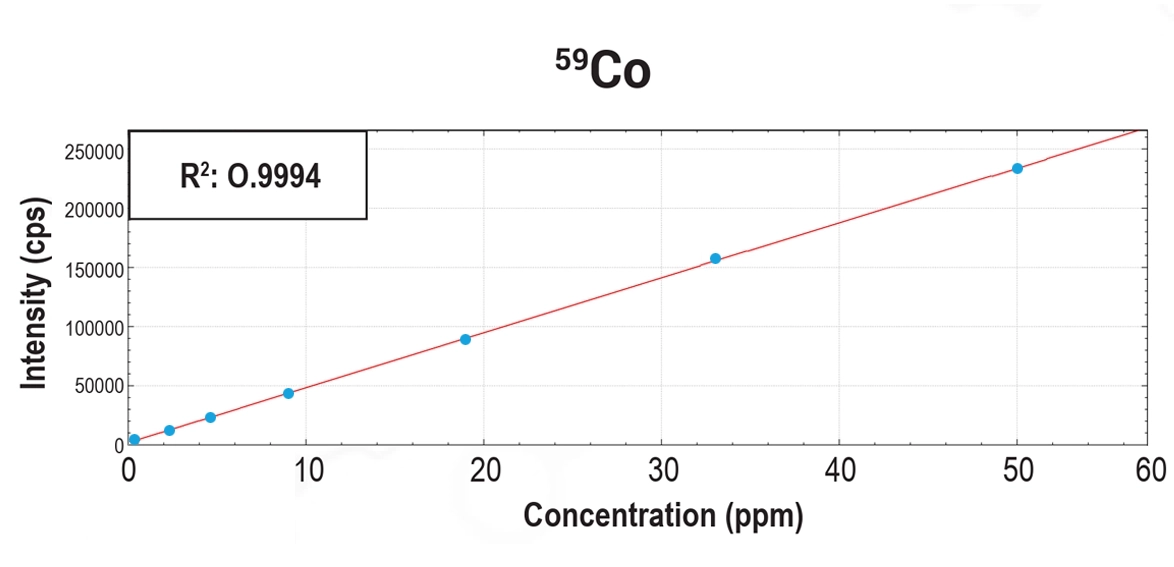

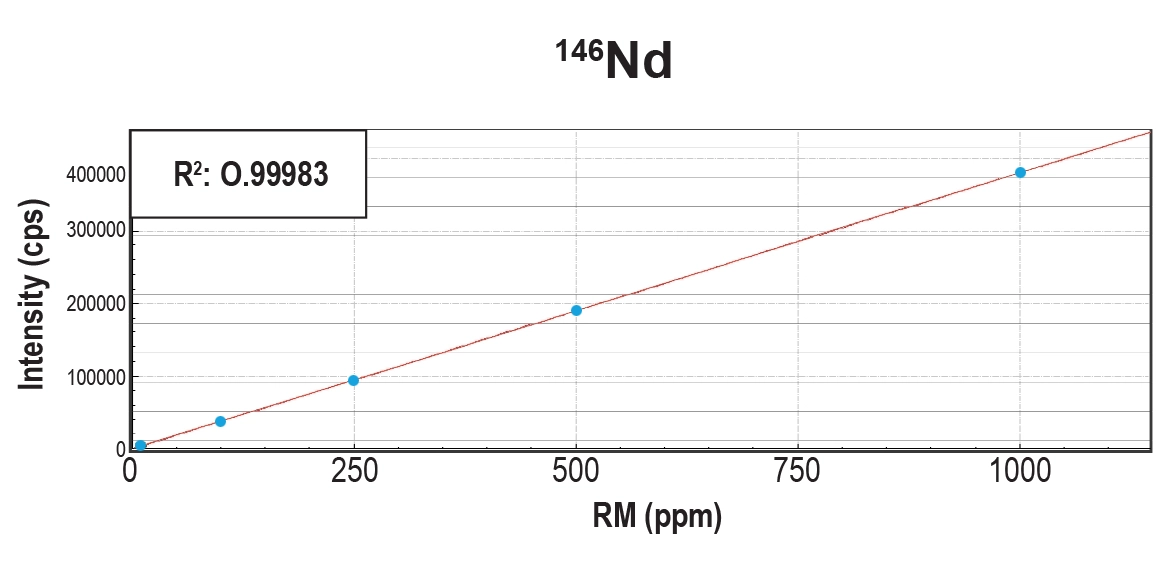

- Solution-Level Accuracy – Consistently achieve R² ≥ 0.995 and often > 0.9995.

- Consistent Data Quality – Matrix-matched calibration standards maintain precise and accurate instrument calibration.

Robotic Sample Handling with Barcode Tracking

- End-to-End Automation – Continuous, 24/7 precision with real-time results and sample tracking through the analytical workflow.

- High-Capacity Analysis – Automated processing of over 1,000 solid samples per run.

- Seamless Data Integration and Reporting - Data is automatically processed with quantified results available for immediate review, reporting, and export to LIMS.

What Makes SolidSample ICPMS Better than the Rest?

Enabled by a robust ion source, multielement measurement capability, and low detection limits, SolidSample ICPMS delivers solution-level accuracy and trace detection directly on solid samples, without the need for acid digestion. With a mass spectrum dominated by singly charged ions, the system ensures stable, predictable quantification, while gas modes and QQQ effectively resolve remaining mass spectral interferences. Automation, together with precision and speed, makes SolidSample ICPMS a highly advanced and efficient approach for direct solids analysis.

- 1. SolidSample ICPMS vs Solution-based Digestion

-

SolidSample ICPMS analyzes solid samples directly, eliminating the need for hazardous and time-intensive acid digestion. By eliminating digestion, it reduces the risks of contamination, sample loss, and chemical waste, resulting in a safer, faster, and more sustainable workflow. Linearity and quantitation remain uncompromised, ensuring the same analytical accuracy as traditional solution-based ICPMS.

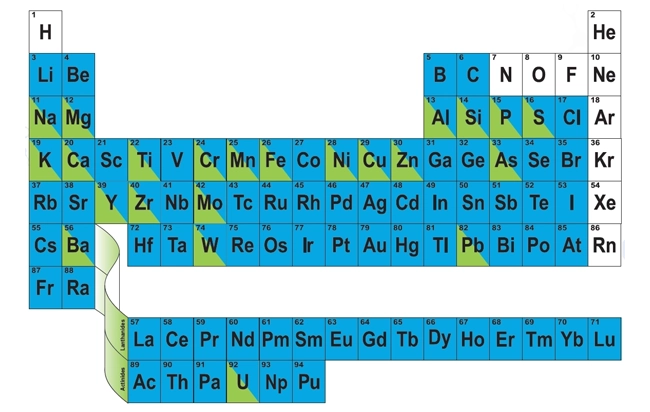

- 2. SolidSample ICPMS vs XRF

-

SolidSample ICPMS achieves low-to-sub-ppb detection limits with true quantitative accuracy. It can detect critical minerals up to 3X below the detection capabilities of XRF, enabling laboratories to characterize trace and ultra-trace elemental signatures with far greater certainty. The system’s direct connection to an ICP or ICPMS ensures efficient transfer and precise measurement of the sampled area without loss or contamination.

- 3. SolidSample ICPMS vs Glow Discharge Techniques

-

SolidSample ICPMS delivers low-to-sub-ppb detection capabilities. A singly charged ion mass spectrum combined with gas modes and QQQ resolve mass spectral interferences. Reusable matrix-matched calibration standards do not expire and ensure consistent accurate results. The high level of automation and rapid sample throughput make it ideally suited for high-volume or complex matrix workflows.

- 4. SolidSample ICPMS vs Spark Source Techniques

-

SolidSample ICPMS offers simple singly-charged mass spectra for clear quantification of most elements in most sample types. Remaining interferences are eliminated using either collision/reaction gases or QQQ ICPMS. Capable of processing dozens to over 1,000 samples per day, at low-to-sub-ppb detection limits, it provides fast, consistent, and reliable results. Automatic data processing delivers meaningful, ready-to-use results that support immediate sample evaluation.

Software

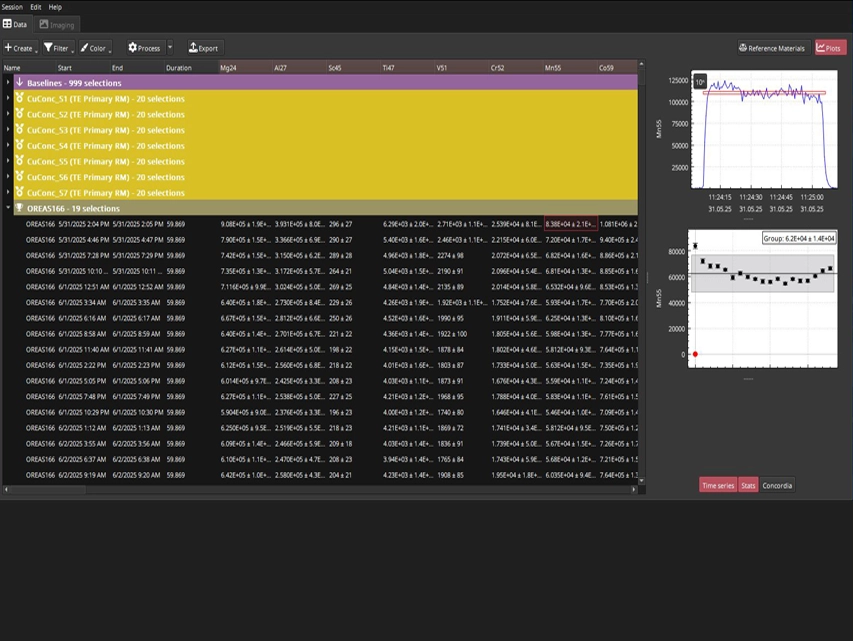

Data Processing Software, Powered by Iolite

SolidSample ICPMS Software uses smart outlier rejection, spline interpolations, and 3D calibrations to deliver the most accurate results possible.

Application Data Quality

Proven Analytical Performance

Calibration curves and element recovery data validate the accuracy, sensitivity, and reproducibility of the SolidSample ICPMS. Across diverse sample types, the system consistently delivers accurate, quantitative results that meet the highest analytical standards.

Application Notes & Files

Explore our collection of SolidSample ICPMS application notes and product resources to discover detailed experiments, techniques, and findings relevant to laser ablation and advanced analytical applications.

Rapid and Accurate Determination of Trace Elements in Copper Concentrate Fused Beads

Determination of REE in Fusions

Automated Multielement Analysis of Large Batches

SolidSample ICPMS vs XRF Periodic Table

SolidSample ICPMS Features Diagram

Customer Service

Expert Support Every Step of the Way

At ESL, we believe in ensuring our client's success through great support. That's why our team will work closely with you throughout the entire process - from the first quote, to long after installation.

Before You Buy

Our team of automation experts will make sure every detail of SolidSample ICPMS aligns with your workflow so you get exactly what you need.

After Purchase

We tailor the system's software methods to match your specific protocols, typically based on your lab's SOPs. You won't be left to figure it out - we'll build your methods for you.

At Installation

ESL experts provide hands-on training to your team, showing how to use the intuitive software and run your methods confidently from day one.

Continued Support

Long after installation, we continue to support you. Whether it's method updates, software questions, or workflow changes, our expert team is always just a call or email away.

Contact Us

Automate Your Lab with SolidSample ICPMS

Have questions or need expert guidance on our SolidSample ICPMS system?

We're here to help you navigate the advanced capabilities and applications of our products. Whether you're seeking technical support, product information, or customized solutions, reach out to our team of experts. Connect with us today to discuss your specific needs and discover how our laser ablation technology can power your lab.